Choosing the Right Robot Payload, Reach & Axis Configuration

Robot automation is no longer a futuristic idea – it’s a business necessity. But when companies decide to automate a process, one question always comes up: Which robot should we choose? The answer depends heavily on three critical factors: payload, reach, and axis configuration.

If you’re evaluating industrial robots for the first time – or refining your existing deployment – this guide will help you make smarter that improve performance and reduce costs.

What Is Robot Payload – And Why It Matters ?

Robot payload refers to the maximum weight a robot can carry while maintaining precision, speed, and safety.

Think of Payload Like a Backpack

Just like a person can’t hike efficiently with a backpack that’s too heavy, a robot can’t perform reliably if its payload capacity is exceeded. Choosing a robot with insufficient payload can lead to :

- Reduced accuracy

- Slower cycle times

- Early wear and tear

- Safety risks

Pro Tip : Always account for the total weight – not just the part, but also grippers, tools, and attachments.

Robot Reach – Cover the Right Distance

Robot reach is the maximum distance a robot’s arm can extend from its base. This determines how much workspace the robot can cover without repositioning.

Why Reach Is More Than Just “Longer = Better”

- Too short → robot can’t reach all work points

- Too long → higher cost, less rigidity

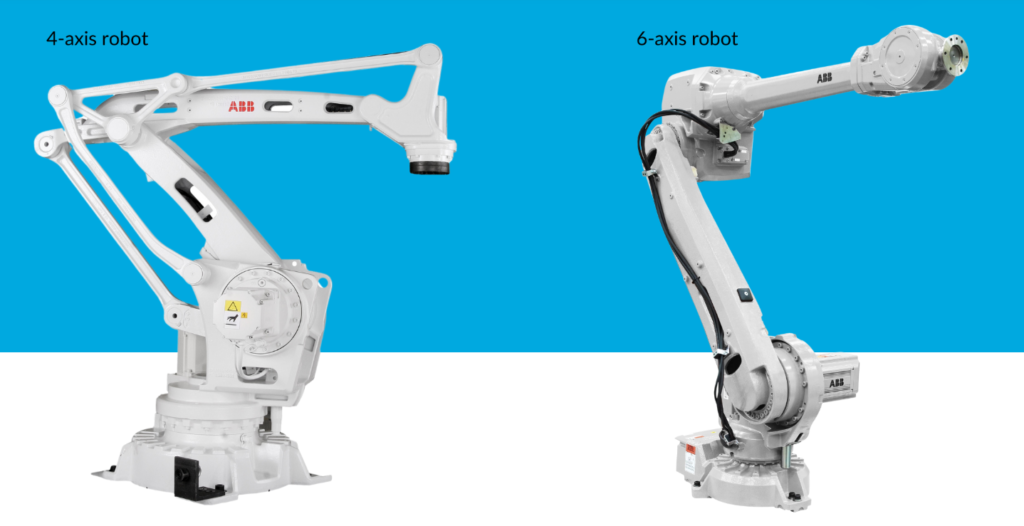

Axis Configuration – The Robot’s Degree of Freedom

Most industrial robots today are described by the number of axes they have and this defines how they move

Common Axis Types :

- 4-Axis Robots – Simple rotation, ideal for palletizing or linear tasks

- 6-Axis Robots – Full flexibility, capable of human-like motion

Which One Should You Choose?

- 4-Axis for repetitive, planar tasks

- 6-Axis for complex trajectories, odd angles, and precision

More axes = more flexibility, but also higher cost and programming complexity.

How to Choose the Right Combination

Choosing the right industrial robot starts with understanding the task requirements, such as whether the application involves lifting heavy parts, handling precise components, or performing repetitive motions. Once the task is defined, the next step is to map the workspace accurately by measuring distances, heights, and required orientations to ensure the robot can operate efficiently within the available layout. Finally, it is essential to match robot specifications to the application needs by selecting the correct payload capacity, including tool weight and an adequate safety margin, ensuring sufficient reach to cover all work zones without repositioning, and choosing the appropriate axis configuration based on the complexity of movement required. This structured approach helps manufacturers optimize performance, improve reliability, and achieve a higher return on investment in robotic automation.

Common Selection Mistakes to Avoid

- Choosing based on price alone

- Ignoring future scalability

- Forgetting end-of-arm tooling in payload calculation

Why It Matters for Your Business ?

The right robot configuration can:

- Maximize productivity

- Reduce operational costs

- Improve safety

- Increase consistency and quality

In contrast, the wrong choice increases downtime, accelerates wear, and drains your budget.

Final Thoughts

Selecting the optimal robot is both science and strategy. By understanding payload, reach, and axis configuration, you empower your automation plans – and ensure the robots you choose deliver real value.

If you’d like expert help in choosing the perfect robot for your application, visit synapse robotics or reach out to our team for personalized guidance.